- (727) 238-2504

- karl.schmitz@aqua-equip.com

- MON - FRI: 8:00 - 6:00pm SAT - SUN: OFF

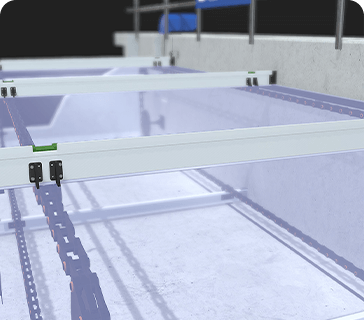

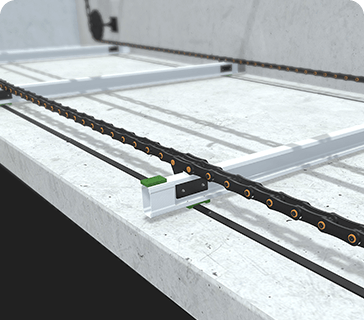

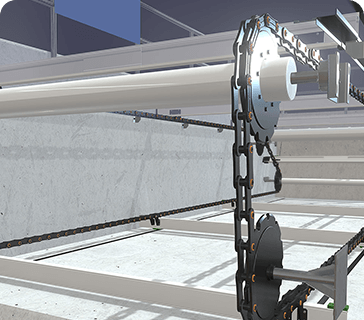

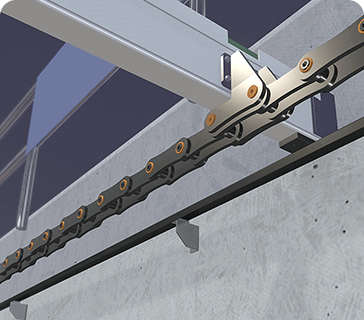

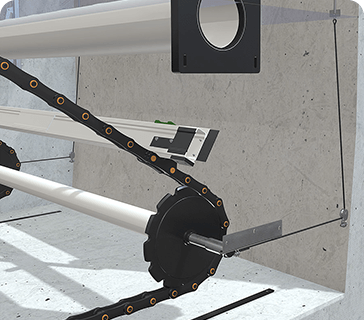

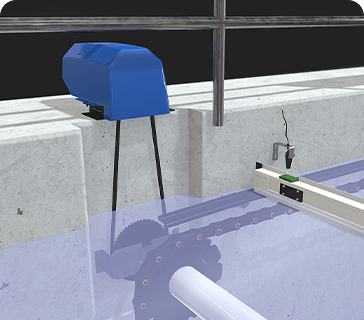

Chain and flight scraper systems are an effective solution for sludge removal in clarifier tanks.

AET offers an endless chain and flight scraper system, renowned for its top-of-the-line performance in sedimentation, flotation, and clarification processes. This system is flexible and can be utilized across various project applications and basin types.

AET chain and flight scraper systems for clarifiers can be used in combination with tube settler systems or in conventional clarifier tanks. AET offers various material options for chain and flight collector chains, shafts, and other components.

Advantages:

The WTP of Hammond, IN supplies up to 80 MGD of drinking water to the city of Chicago and the surrounding area. AET in collaboration with AECOM provided a turnkey clarifier system including tube settlers, support structure, catwalks, baffle walls, and effluent collection system. Since the clarifier basins are underground, all equipment had to be designed to fit through a 4ft manhole.

AET provided full replacement for a turnkey tube settler clarifier system including support structure, stainless effluent troughs, baffle walls and water stop gates. The plant flowrate capacity was increased from 16MGD to 20MGD by using AET high performance LS50 tube settlers.

AET retrofitted a Densadeg® high rate clarifier system in Texas, USA. The previously used PVC tube settlers were partially clogged and deteriorated caused by sunlight and UV radiation. The AET scope of supply included a new supporting structure, tube settlers for a round tank shape and improvements on the existing effluent launders.

AET provided engineering support for the design of an on-campus WWTP in Florida, USA. At the same time we supplied new tube settlers which are tested for different flow rates and solid levels.

2024 Aqua Equip Technologies LLC – All Rights Reserved

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |