Case Studies

Fixed bed bio reactor (FBBR) – Poultry processing plant

April 22, 2019

Situation: The Hurlock, MD poultry plant processes about 300,000 chickens per day which equals a total flow of 1.3MGD (4 gallons per bird). The existing process

Densadeg® retrofit, TX, USA

AET retrofitted a Densadeg® high rate clarifier system in Texas, USA. The previously used PVC tube settlers were partially clogged and deteriorated caused by sunlight and UV radiation. The AET scope of supply included a new supporting structure, tube settlers for a round tank shape and improvements on the existing effluent launders.

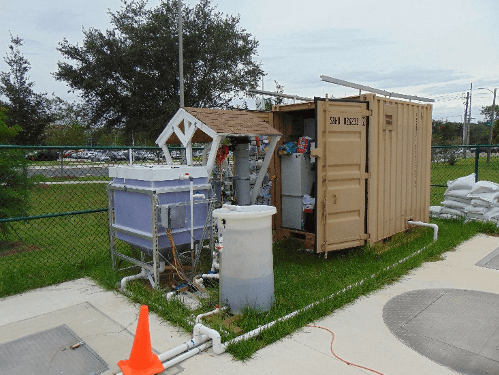

Campus WWTP, FL, USA

AET provided engineering support for the design of an on-campus WWTP in Florida, USA. At the same time we supplied new tube settlers which are tested for different flow rates and solid levels.

Wisconsin, USA

AET LLC retrofitted a sedimentation basin for coal and sand removal with new Polypropylene, equidistant tube settlers. The prior used PVC tube settlers were heavily damaged after only 5 years of operation because of a wide range of impacts such as high solid concentrations and abrasive materials.

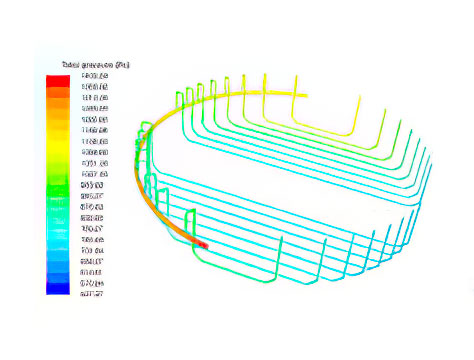

Calgary, Canada

AAET LLC retrofitted an existing sedimentation tank for solid settling in a mining application. Also included in the scope of supply was an extensive engineering design and CFD simulation to improve the flow pattern inside the sedimentation tank.

Lagoon upgrade with FBBR, MS, USA

AET in cooperation with Jaeger- aeration provided a FBBR system (incl. piping and blower setup) as an upgrade for a lagoon treatment plant in Mississippi, USA. Part of the influent water is going through the FBBR side stream to fulfill BOD and ammonia permits.

Trickling filter air distribution system, NY, USA

To remove odors from a trickling filter plant an air distribution system was installed underneath the fill media during a retrofit project. The distribution system is evenly releasing air so that the odors are removed when passing the biofilm fill media. AET assisted with the design and calculations of the trickling filter air distribution system.

Drinking water plant WV, USA

AET retrofitted a 14MGD drinking water plant. The scope of supply did not only include new AET NSF-approved PP tube settlers but also a new support system, effluent launders, baffle walls and other equipment. The former PVC tube settlers were replaced by more robust PP tube settlers.

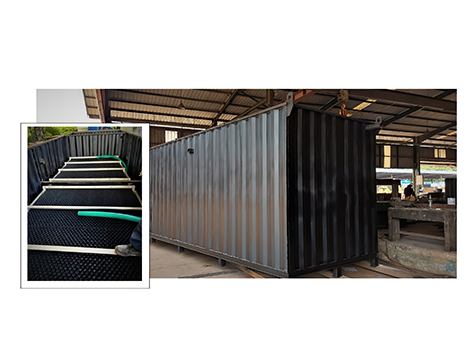

Containerized wastewater treatment plant Sri Lanka

In collaboration with a local contractor AET developed and build containerized wastewater treatment plants for a university and industrial park in Sri Lanka. The 40ft container plants include fixed bed reactor for BOD removal, tube settler clarifiers and controls.

FBBR and clarifier system, Costa Rica

AET provided FBBR reactor units and a tube settler system including sludge scraper, support structure and effluent launders for an industrial park in Costa Rica. AETs engineering support included aeration sizing and setup as well as tank design for optimal flow distribution within FBBR tanks and improved sludge removal in clarifier tanks.

Tube settler for brewery plant OR, USA

AET provided FBBR reactor units and a tube settler system including sludge scraper, support structure and effluent launders for an industrial park in Costa Rica. AETs engineering support included aeration sizing and setup as well as tank design for optimal flow distribution within FBBR tanks and improved sludge removal in clarifier tanks.

Freestanding tube settler clarifier Nigeria

A food processing company in Nigeria needed to add clarifier capacity to an existing plant. After discussing the option of a conventional clarifier tank the client decided for an AET containerized tube settler tank. The tube settler tank does not only have lower costs compared to a conventional clarifier but it also requires less space.