Tube settlers

Tube Settler/Lamella Clarifier Packs

Equidistant, high- stability PP tube settlers

- Equidistant channels provide maximum surface area

- Polypropylene material extends product lifetime

- Higher material thickness provides high product stability (walkable design)

- Tongue and groove system allow easy onsite assembly

- Large channel opening size reduces the risk of clogging

Fields of application

- TSS removal and particle separation

- Upgrade of existing sedimentation tanks

- Tertiary or secondary clarification for municipal WWTP

- Drinking water

- Process water applications

Advantages Of Tube Settler Systems

- Significant reduced tank size

- High mechanical strength

- Assembly process allows flexible tank geometries and shapes

- Complete package (support, anti-floating, sludge removal and water effluent) out of one hand

- Chevron shaped channel design offers most surface and best solid discharge

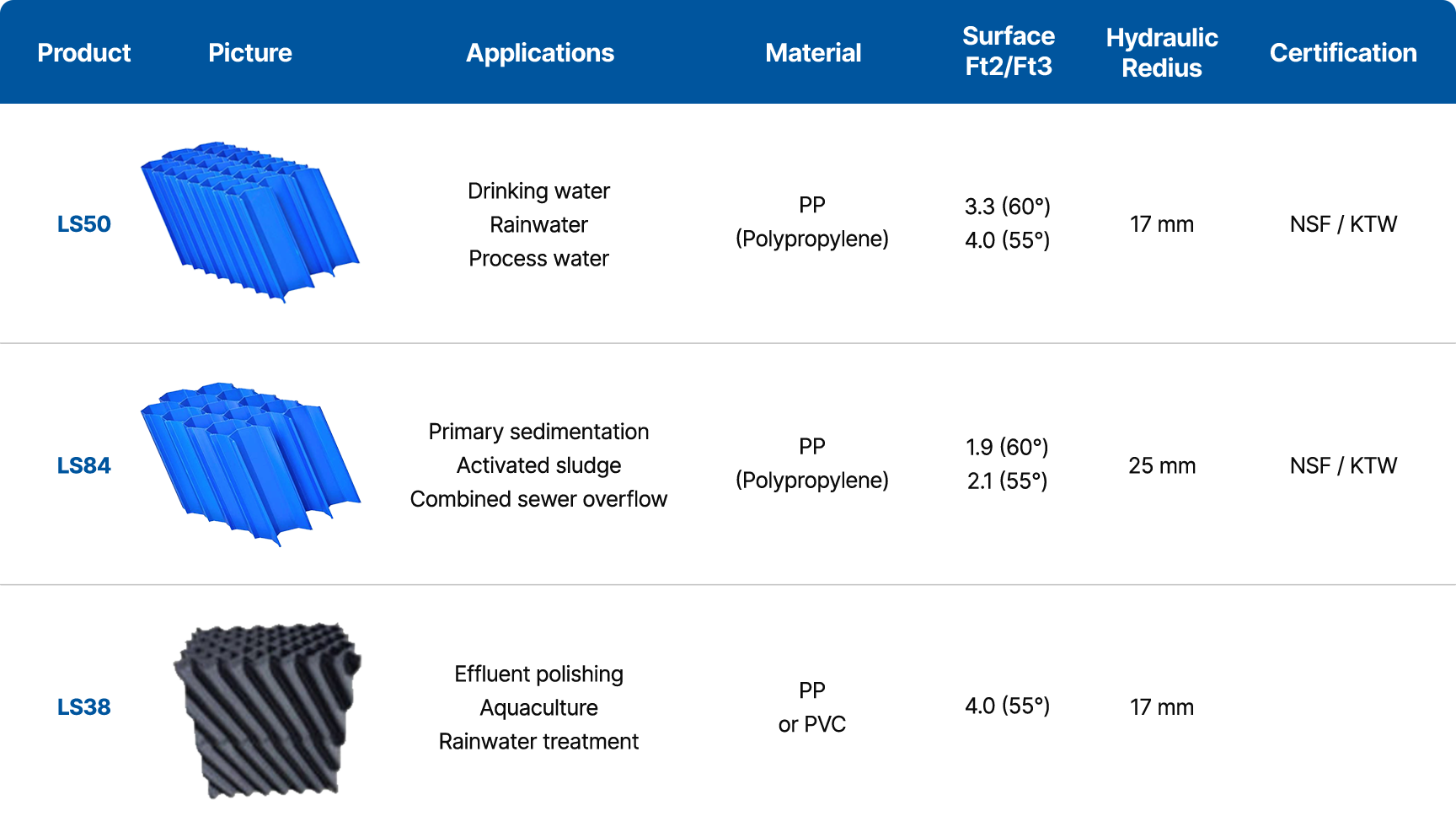

Product: LS84

Product: LS50

Tube settler model specifications

References

Indiana, USAReferences

West Virginia, USAReferences

Densadeg® retrofit, TX, USAReferences

Campus WWTP, FL, USAReferences

Indiana, USA

The WTP of Hammond, IN supplies up to 80 MGD of drinking water to the city of Chicago and the surrounding area. AET in collaboration with AECOM provided a turnkey clarifier system including tube settlers, support structure, catwalks, baffle walls, and effluent collection system. Since the clarifier basins are underground, all equipment had to be designed to fit through a 4ft manhole.

West Virginia, USA

AET provided full replacement for a turnkey tube settler clarifier system including support structure, stainless effluent troughs, baffle walls and water stop gates. The plant flowrate capacity was increased from 16MGD to 20MGD by using AET high performance LS50 tube settlers.

Densadeg® retrofit, TX, USA

AET retrofitted a Densadeg® high rate clarifier system in Texas, USA. The previously used PVC tube settlers were partially clogged and deteriorated caused by sunlight and UV radiation. The AET scope of supply included a new supporting structure, tube settlers for a round tank shape and improvements on the existing effluent launders.

Campus WWTP, FL, USA

AET provided engineering support for the design of an on-campus WWTP in Florida, USA. At the same time we supplied new tube settlers which are tested for different flow rates and solid levels.

Articles & Literature